21.02.24

The renaissance of cleaning textiles

The world of cleaning textiles is often viewed somewhat disparagingly. Cleaning cloths are colloquially referred to as 'rags' and most non-specialists still think that a fringed mop is the appliance of choice for floor cleaning. However, times have changed massively.

The cleaning sector is not known as innovation-driven as certain other industries. The tried and tested is preserved. Innovative novelties are tested somewhat cautiously at first. However, high-quality high-tech materials are used in cleaning textiles these days. Processing is complex and is carried out according to the latest industry standards. The end products are effective tools that have nothing in common with the old dusting cloths and cotton fringed mops.

The raw materials

Cotton fibers continue to play an important role. Cotton fibers are soft and absorbent, which is essential in some areas of application. However, the water consumption for the production of cotton is very high and the use of pesticides in cotton cultivation is also considerable. Therefore, the fiber no longer really fits into the modern understanding of sustainable raw materials.

In addition to cotton, cellulose is also an important plant-based raw material. Cellulose is the largest component of plant cell walls. As wood is the highest quality source of cellulose, one would think that cellulose can be used without any major concerns. However, as cellulose is also a by-product of cotton production, this puts the positive ecological balance into perspective. Reputable sustainability labels should therefore be taken into account.

Linen is mostly used as half-linen, i.e. mixed with 50% cotton, in dish drying cloths.However, linen fibers are hardly used in cleaning textiles today.

Polyester and polyamide are the main raw materials for the production of microfibers in various blending ratios, depending on the area of application. Microfibers are the most important fibers in professional cleaning today. The specific properties of these fibers are predestined for use in the cleaning sector. The advantages of these fibers are explained in the following chapter.

Polyurethane is used in the form of sponges, coating on microfiber cloths (foam) as a substitute for the classic chamois leather and sometimes also as a mixed component in scrubbing machine pads.

Bamboo is a new raw material in the cleaning textiles sector. As the bamboo plant (sweet grass) usually grows back quickly, it is cheap to produce and also has a positive ecological balance. Bamboo grows in forests with a capacity of 10 to 15 tons of biomass per year under sustainable management. However, it should be noted that bamboo fiber is actually too short to be spun. Therefore, cellulose is first produced from the raw material bamboo and then a viscose fiber is obtained. This is then spun and processed into cleaning textiles.

Microfiber as an important raw material in cleaning textiles

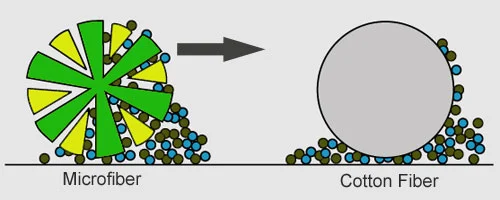

What exactly is a microfiber? By definition, a microfiber is a fiber that weighs just 1 gram per 100 km length. It is made either from pure polyester or blended with polyamide. The mixing ratio depends on the intended use of the end product.

There are two main steps in the manufacturing process. First, the actual spinning takes place. Here, very pure raw materials are spun at high speed into a so-called multifilament. These are intertwined fiber strands that are produced as a primary product. These multifilaments must be split for use in the final product.

The splitting of the multifilament creates the microfiber as we know it and as it is commonly used in the cleaning industry today. The microfiber can only show its superiority through splitting. It can then pick up dirt and have an abrasive effect on the surface. There are three main methods for splitting: water jet splitting, steam splitting and thermal splitting. The thermal gritting process is most commonly used.

Due to the magnetic effect of the microfiber on dust (thanks to the raw materials polyester and polyamide), it binds it to itself. It is also very good at absorbing liquids as it has countless pores and air chambers. The liquid can penetrate these and is stored in the cleaning textile. During the cleaning process, the moisture is then released again and is available for cleaning.

Summary

Microfiber is the most important type of fiber used in cleaning textiles today. It is usually made from polyester or blends of polyester and polyamide. However, the other raw materials still have their justification as starting materials for specific applications and in special products (e.g. dust wipes for high-gloss surfaces). The ecological balance is different for all raw materials and should also be taken into account.