01.06.23

The key to mold prevention: surface treatments

Mold Remediation: The choice of surface coating is crucial for a sustainable outcome.

Basics

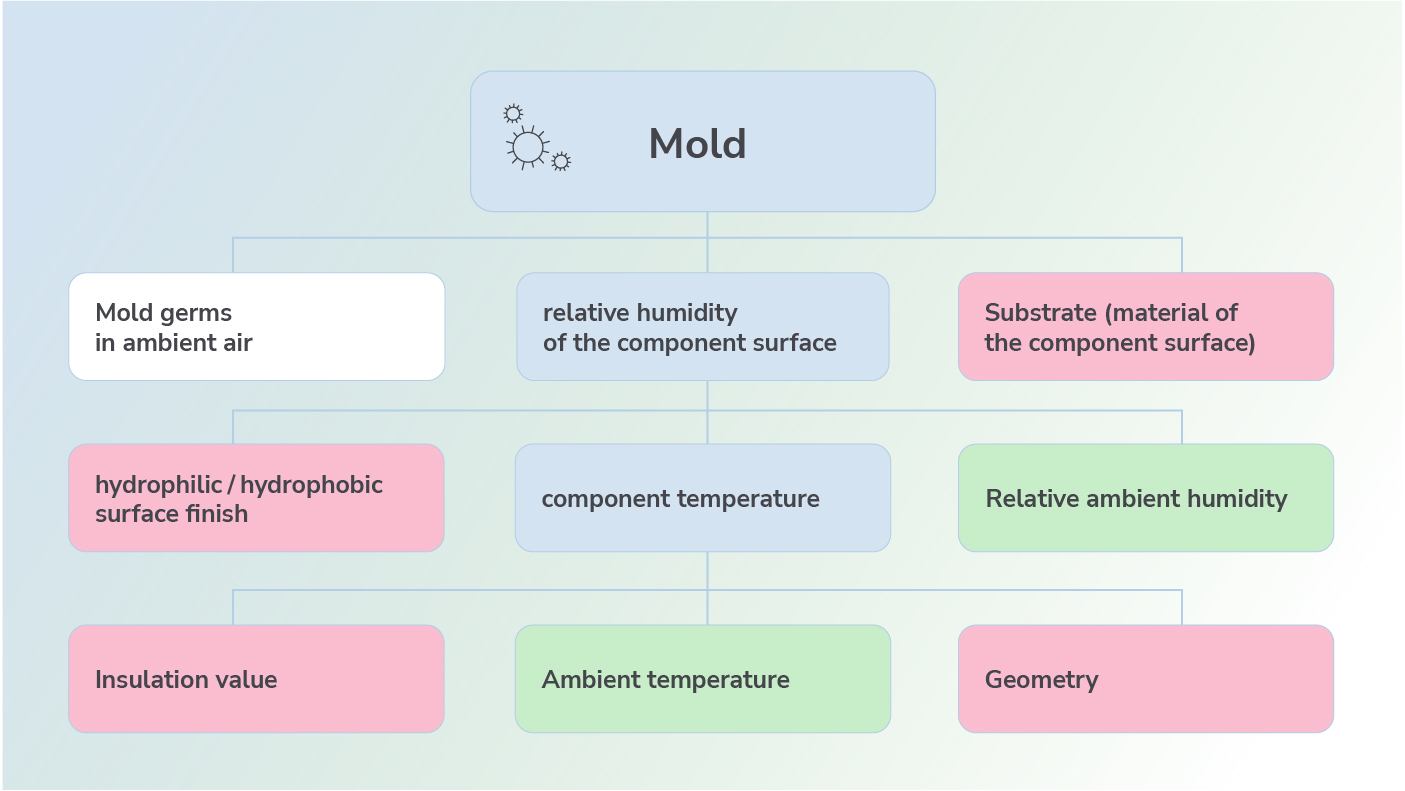

The three essential factors influencing the germination and growth of mold are:

- The presence of mold spores in the air. Spores naturally exist everywhere. If the concentration in the indoor air is relatively high compared to the outdoor air, the presence of a mold source in the space is to be expected.

- The availability of a suitable substrate. Excellent substrates include drywall and cellulose; mold grows poorly on clean glass.

- The moisture on the building surface. There can be various reasons for excessive localized moisture, such as high relative humidity combined with thermal bridges, water damage, inadequate insulation, etc.

Factors in green can be influenced by residents

Factor in gray can only be influenced to a limited extent

Factors in blue are factors that are dependent on other factors

When all three conditions are met simultaneously and in the same location, potentially harmful mold can develop.

The following discusses the topic of surfaces and surface conditions in relation to mold remediation. The choice of building surface material determines whether an optimal or suboptimal substrate for mold is introduced. Therefore, the restorer or builder has control over the mold’s “menu” when selecting the building surface. Depending on the choice, it may or may not appeal to the mold. In this context, professional literature refers to substrate groups.

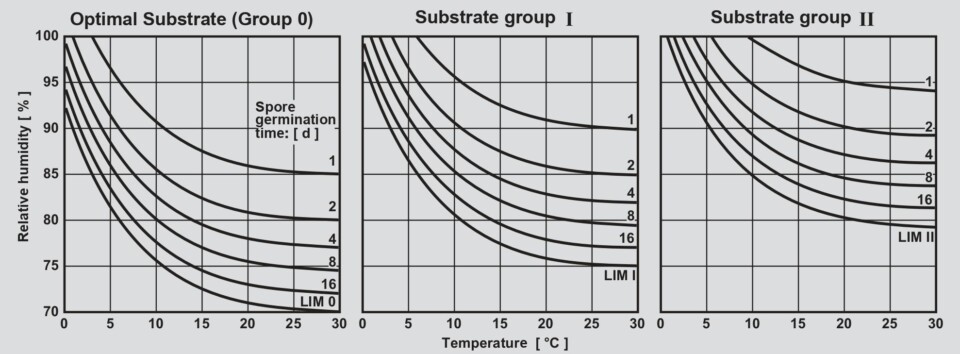

- Substrate Group 0 includes optimal substrates such as agar, full media, especially for laboratory use.

- Substrate Group I consists of materials like drywall and fiber wallpapers.

- Substrate Group II includes materials like mineral paints, metals, glass, or lime.

Molds germinate and grow most rapidly on materials belonging to Substrate Group 0. The level of surface contamination is also a significant factor. A surface categorized under Substrate Group II can become an optimal substrate for mold when it is dirty. In practice, elevated relative humidity on building surfaces is often attributed as the primary cause of mold occurrence. This humidity is determined by the ambient relative humidity, the building component temperature, and the surface condition of the building element.

The relative humidity in a room is influenced by the user’s ventilation behavior. In residential settings, it’s the occupants, while in the industrial sector, automatic ventilation systems play a role. The building component temperature is primarily influenced by geometry (geometric cold bridge), ambient temperatures (temperature differences between outside and inside), and the insulation value. When the surface temperature of the building component drops to or near the dew point, condensation forms on the surface (this process can be illustrated on a Mollier diagram). On a hydrophobic surface, this condensation remains on the surface, providing the basis for mold growth. Condensation can only be removed from the surface through evaporation, and the rate of evaporation depends, in part, on the wetted area. Water formed as droplets evaporates more slowly than water that has spread out like on a blotter. Choosing a hydrophilic surface condition, designed to break the surface tension of condensation (like a blotter), increases the rate of evaporation. This keeps the surface dry and deprives mold of a foundation for growth. Hydrophobic surfaces (e.g., dispersion paints) cause condensation to remain in the form of droplets on the surface, keeping it wet and moist for an extended period.

With knowledge of the building component temperature, humidity values in the environment, and the substrate group, it’s possible to predict the occurrence of mold using the Isopleth system developed by Sedlbauer [1]. In other words, it can be determined when the mold will germinate and at what rate it will grow. For example, in a room with a temperature of 20°C and 60% relative humidity, having a cold bridge with a wall temperature of 15°C and assuming a material from Substrate Group II, the relative humidity near the wall is now 82%. Under these conditions, it takes approximately 8 days for mold to germinate on a hydrophobic surface, and it grows at a rate of about 1 mm per day. If you were to use a material from Substrate Group 0, germination would occur in less than a day, and growth would be around 3 mm per day.

Implications for new construction or renovations

For exterior walls, especially in the areas of geometric thermal bridges, we recommend the application of anti-condensation coatings. This can significantly prevent the occurrence of surface-bound condensation that doesn’t evaporate. We do not recommend applying dispersion paints to these areas, as these paints are only mildly hydrophilic, with a low evaporation rate.

Implications for mold remediation

In practice, it is often observed (particularly in residential settings) that wallpapers are reapplied after mold removal for aesthetic reasons. However, from a mold prevention perspective, this approach is entirely incorrect. Wallpapers often consist of cellulose, which falls into Substrate Group I, making them a good substrate for mold. Even in cases of mold remediation, we strongly recommend using hydrophilic surface coatings. There are now products on the market that not only have moisture-absorbing properties but also break the surface tension of condensation, leading to significantly higher evaporation rates, known as anti-condensation coatings. The result is dry building surfaces.

A word on the topic of interior insulation

In our opinion, the installation of interior insulation is not necessarily advisable. From a thermal perspective, interior insulation results in the room’s heat being isolated from the exterior wall behind the insulation, while the exterior wall remains fully exposed to the cold outside temperatures. The desired effect of increasing the temperature of the building surface, thereby moving it away from the dew point, is often achieved to only a very small and therefore insignificant extent. What’s more concerning is the risk of hidden mold formation between the insulation and the exterior wall.

Summary

A crucial factor in mold prevention and remediation is the choice of the right surface coating. Working with hydrophilic materials, whether in new construction or after mold remediation, can be a significant step in ensuring that mold either does not form or does not reappear.

Literature:

- [1] Neue Erkenntnisse zur Beurteilung von Schimmelpilzen und Stand der Normenbearbeitung. 2002 Klaus Sedlbauer et al.