31.03.23

Classification of cleanrooms according to ISO

In general, a cleanroom can be defined as a space that is constructed and designed to control the level of particle contamination of various sizes per unit volume in the air within specific zones. The classification required for a cleanroom is detailed in the following report.

ISO, the International Organization for Standardization, is an independent international association of standardization bodies with members from 167 countries. It is a non-governmental organization based in Geneva, Switzerland. ISO has published an extensive series of standards, including those related to cleanrooms. Cleanrooms play a crucial role in various high-tech industries, enabling processes that would otherwise be impossible. They are utilized in industries such as semiconductor manufacturing, medical technology, laboratories, aerospace, food production, chemical and pharmaceutical manufacturing, and the automotive industry. Cleanrooms are also essential in nanotechnology, although they are regulated by a different standard (ISO/TC 229 Nanotechnologies).

Cleanroom clasification

The required classification for a cleanroom depends on the demands placed on the product being produced. Naturally, cleanrooms become more cost-intensive as the requirements and classification level increase. In general, a cleanroom can be defined as a constructed and designed space intended to control the level of particle contamination of various sizes per unit volume in the air within specific zones [1]. Ventilation systems that regulate parameters such as temperature, humidity, air flow, and air purity play a significant role in this control.

The following standards are of utmost importance for cleanrooms:

- ISO 14644

- ISO 14698

- GMP EU Classification

For the United States, the FDA defines cleanroom norms, especially for pharmaceutical applications and the food industry [2]. Additionally, GMP classification distinguishes between at-rest and operational states [3]. The at-rest state refers to the absence of personnel in the cleanroom, with all equipment in standby mode [1,3]. Cleanroom users are mainly concerned with the specifications during operation. It’s important to note that particles can enter the cleanroom not only from the outside but also from objects and individuals inside, emitting and circulating contaminants. The latest revision of Annex 1 places more emphasis on examining garments and personnel inside the cleanroom, including proper movement within the cleanroom. Furthermore, requirements for cleanroom garments are more precisely specified (correct sizing, how to wear cleanroom attire, etc.). The document now also describes items that are prohibited in a cleanroom, such as guidelines for handling mobile devices, while emphasizing the importance of training [3].

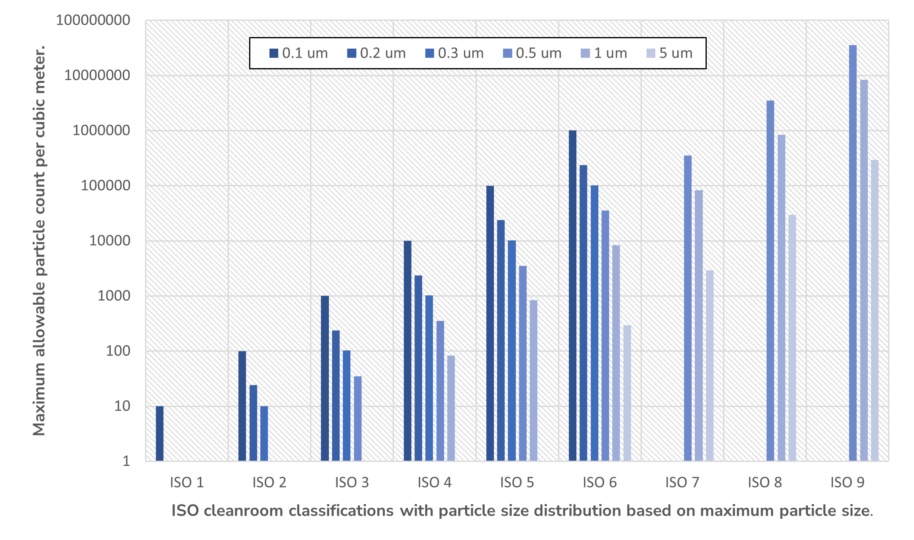

The following table is based on the tabular classification according to ISO 14644-1: 2015 – Part 1: Classification of air cleanliness by particle concentration [1]. A slightly different presentation is used to facilitate better comparison between classifications. It’s important to note that the concentrations are cumulative. The columns in each iso-class do not represent a particle size distribution but rather the maximum allowable count. So, only one column applies. For iso-classes > ISO 6, smaller particles (<0.3 µm) are no longer specified due to their high quantity, making them difficult to count. Particles smaller than 0.1 µm also cannot be considered.

To get a sense of the classifications, it’s helpful to put the size ratios into perspective. One way to do this is by comparing the size of a tennis ball to that of a grain of salt. If you mentally shrink the tennis ball to the size of the grain of salt while simultaneously shrinking the grain of salt, you’d find yourself in the range of a few micrometers:

| size in mm | size in µm | |

|---|---|---|

| Tennis ball | 100 | 105 |

| grain of salt | 1 | 103 |

| see examples in the following images | 0.01 | 10 |

The following images illustrate some examples in 1 µm [4]:

Image size: 1 µm.

Image size: 10 µm.

Image size: 60 µm.

Literature

- [1] ISO 14644-1:2015

- [2] Gaurav A. Chaudhari, Suhas H. Sarje: Clean Room Classification for Pharmaceutical Industry. International Journal of Engineering and Technical Research (IJETR), vol 3, 4, 2015

- [3] Tim Sandle: EU GMP Annex 1: What The ‚Final‘ Draft Reveals. GXP, vol 24, 2, 2020

- [4] Bilder gedruckt mit freundlicher Genehmigung der Nanosurf AG, Liestal. www.nanosurf.com.

Tell us what you think

Be the first to comment this post.

You must be logged in to leave a comment.